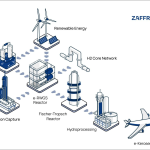

An international consortium has been formed to produce sustainable aviation fuels in Germany by combining carbon dioxide extracted from cement production with green hydrogen generated from wind and solar energy. CEMEX, a global construction materials group headquartered in Mexico, will supply CO2 generated at its cement plant in Rüdersdorf, near Berlin, the green hydrogen will come from the German renewable energy company ENERTRAG and the ecoFT business unit of South African energy and chemicals group Sasol will provide the technology to convert the combined CO2 and hydrogen to e-kerosene for blending with jet fuel. The three companies are equal partners in the newly-founded venture, Concrete Chemicals GmbH. The project is significant as it singly reduces the emissions of two hard-to-abate global industries, air transport and cement production, and will contribute to the EU’s planned mandatory minimum blending quota for power-to-liquid (PtL) e-kerosene, reports Tony Harrington.

Around 60% of carbon emissions in the cement production process comes from the chemical reaction that occurs in cement kilns. CEMEX operates 63 cement plants globally, and by 2030 wants its Rüdersdorf facility to be the world’s first to achieve net zero emissions. Through its venture capital division, CEMEX Ventures, the company is partnering with a range of industries to help achieve carbon neutrality through the use of technologies that can capture, store or recycle CO2 emissions created in making cement. A Rüdersdorf carbon neutral alliance has been formed that includes over 20 startups, universities, authorities and companies from other industries to develop industrial-scale solutions.

“We are excited to be part of this groundbreaking project that will contribute to the decarbonisation of two of the world’s key industries,” said Fernando Gonzalez, the Chief Executive Officer of CEMEX, which initially will provide the project with 100 tonnes of CO2 per day from the Rüdersdorf plant. “The path to carbon neutrality will be built with innovation, and we remain committed to being at the forefront in developing new circular technologies and processes.”

The project has two scaling stages and in the first phase, 15,000 tonnes of e-kerosene will be produced annually. The 100 tonnes of CO2 captured at the Rüdersdorf site daily will be combined with 12 tonnes of hydrogen, produced on site with electricity from regional renewable energy plants, for use in PtL production. In the second stage, the aim is to receive larger quantities of hydrogen by pipeline. The green hydrogen will be produced as part of the ENERTRAG-IPCEI ‘Electrolysis Corridor East Germany’ project, which will have an electrolysis capacity of 210 MW, and capability for the production of 35,000 tonnes of e-kerosene annually. The Concrete Chemicals venture will connect to other ongoing hydrogen projects in Germany.

ENERTRAG, based in Brandenburg, Germany, develops, constructs and operates integrated energy plants in 10 countries, producing green hydrogen from wind and solar power, while Sasol Group is a specialist in the development and use of Fischer-Tropsch (FT) technologies, which convert green hydrogen and carbon emissions to sustainable fuels and chemicals. In this project, the e-kerosene produced will, once certified, be suitable for blending to constitute up to 50% of jet fuel.

“Sasol is proud to be an active member of this consortium that paves the way for climate-neutral cement production and sustainable aviation fuels,” commented Dr Helge Sachs, SVP Sasol ecoFT. “We look forward to contributing towards decarbonising aviation with our cutting-edge Fischer-Tropsch technology and fulfil our purpose of innovating for a better world.”

To implement the project, the consortium is preparing funding applications, which it said “will be notified at a European level”.

Photo: The CEMEX Rüdersdorf site

More News & Features

Concrete Chemicals consortium secures €350m public funding for German eSAF project

New studies confirm minor flight re-routing to avoid contrails would have major climate benefits

EU SAF mandates will have to be revised, predicts French oil chief

Swiss advanced SAF technology startups Metafuels and Synhelion reach project milestones

PtX fuels have significant Asia-Pacific potential but face many barriers, finds report

EU states to mobilise 500 million euro support for early-mover eSAF production startups