US waste-to-jet fuel technology company Fulcrum BioEnergy has announced plans to create a new £600 million ($800m) facility in North-West England that will convert non-recyclable household waste into around 100 million litres (26.4m US gallons) of low-carbon sustainable aviation fuel (SAF) annually. Fulcrum is joining forces with Essar Oil UK, an energy company whose main asset is the Stanlow Manufacturing Complex, situated south of the Mersey Estuary, with one of the most advanced refineries in Europe that produces over 16% of the UK’s road transport fuels. The new plant, named Fulcrum NorthPoint, will be located within Stanlow and is expected to supply SAF to airports such as Manchester. Fulcrum will construct, own and operate the plant, which will convert several hundred thousand tonnes of pre-processed, non-recyclable waste into SAF. As well as providing the site, Essar will assist with the blending and supply to airlines, and subsidiary Stanlow Terminals will provide product storage and logistics solutions for the project under a long-term agreement. Fulcrum is the second US company in a week to indicate SAF production expansion plans in the UK.

Founded in 2007, Fulcrum is currently commissioning what it says will be the world’s first commercial waste-to-transportation fuels plant in Nevada, which is expecting to start production later this year with a capacity of 11 million gallons per year. The company has already secured investment from BP, Cathay Pacific and United Airlines and Stanlow will be its first plant outside the United States.

“We are excited to be announcing this project, located within one of the UK’s most important energy producing assets, which will help reduce the burden on landfills and industry’s reliance on fossil fuels,” said Jeff Ovens, Managing Director, UK & Europe for Fulcrum.

Plans for Fulcrum NorthPoint are expected to be completed towards the end of this year or early 2022, said the company, and, subject to planning consent, could be operational in late 2025.

Stanlow was acquired by Indian conglomerate Essar from Shell in 2011 and is the second largest oil refinery in the UK, with a capacity of 12,000 million tonnes per year, including production of 2 billion litres of jet fuel that mostly goes to Manchester Airport. Essar Oil UK is a portfolio business of Essar Global Fund, whose companies have aggregate revenues of $12 billion a year.

“Our sights are firmly set on helping to drive the UK’s decarbonisation strategy,” said Essar Oil UK CEO Stein Ivar Bye. “This landmark development supports our long-term sustainability ambition to deliver the energy solutions of the future and position Stanlow as the UK’s leading sustainable aviation fuel hub.”

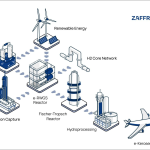

The venture will fit into Essar’s wider objective to build a green energy industrial cluster at the Stanlow site, which announced recently its participation in the production of blue hydrogen under the HyNet North West project. As the UK’s first low-carbon hydrogen hub, HyNet will initially deliver 3 terawatt-hours of hydrogen annually from 2025 to industry, including Essar, and to fuel buses, trains and vehicles as well as home heating. Natural gas and fuel gases from the Stanlow refinery will be converted into low-carbon hydrogen, with CO2 captured and stored offshore.

Stanlow Terminals is the newest and largest third-party liquid storage business in the UK, controlling 3 million cubic metres of capacity. It will provide dedicated tank capacity for the storage and blending of fuel products from Fulcrum NorthPoint and will also utilise direct pipeline access to pump and transport the SAF to airports through the Manchester Jet Line and the UK Oil Pipeline network.

“By offering efficient low-carbon logistics solutions to develop third-party business, we support diversification of the traditional refinery business and become a fundamental part of the UK drive to become carbon neutral,” said Patrick Walters, CEO of Stanlow Terminals.

Fulcrum claims lifecycle emission reductions of around 70% compared to conventional crude oil result from its propriety process, with a local air quality benefit of a 90% reduction in particulates. The 100 million litres of SAF expected to be produced at Fulcrum NorthPoint compares with 60 million litres that the BA/Velocys Altalto facility in North-East England is planning to produce from household and commercial waste.

“Utilising the world-class facilities at Essar, including the impressive jet fuel storage facility at Stanlow Terminals and direct pipeline to UK airports, Fulcrum, along with its current and future investors, will be able to build and operate its facility more efficiently,” said Ovens. “It sets the ‘gold standard’ for SAF production by fully integrating its new, low-carbon fuel technology directly within an existing refinery.

“Locating this facility in the north-west of England at a strategic location will create new, skilled jobs while simultaneously contributing to the UK’s Net Zero 2050 objectives.”

The project will create around 800 direct and indirect jobs during the design, build and commissioning process and over 100 permanent jobs during operation.

Commenting on the announcement, UK Aviation Minister Robert Courts said: “This is great news for the North-West, with hundreds of jobs created as the region takes the lead in making aviation greener. I hope this is a sign of great things to come as we look forward to a sustainable low-carbon future for aviation, helping us push forward towards our 2050 net-zero target.”

Ovens told GreenAir that no other partners or offtake customers are as yet involved with the project and Fulcrum is providing the investment and managing all engineering activity during the initial planning and definition phase. He said potential equity investment will likely be discussed with Essar at a later stage.

“Once we’ve reached a number of milestones associated with the development, we will invite interest from parties such as Essar and our other partners,” explained Ovens. “In the near-term, though, it will solely be a Fulcrum-managed development. We will have discussions with potential airline customers when the time is right as we want to concentrate on advancing the project a little bit further first.”

He said the inclusion of aviation in the UK’s renewable transport fuel obligation (RTFO) was a major factor in attracting Fulcrum to set up its first facility outside the US, and there could be more, he added. “There are a number of UK locations we are looking at.”

He would, though, like to see more policy support that would help make the financing of projects such as Fulcrum’s easier, for example through offering loan guarantees, as is the case in the United States. The announcement late last year by the UK Chancellor of a National Infrastructure Bank could be of specific benefit but details were still awaited, he said.

“However, support for sustainable aviation fuels being part of official policy by the UK government helps tremendously and the recent establishment of the Jet Zero Council and other announcements, plus the availability of grants, draw you to a country,” he said. “The UK waste market is also very mature so there are a lot of benefits for a company like ours. The UK is a great place to invest.”

He said Fulcrum had plans to look at opportunities in Europe, particularly with blending mandates now under strong consideration by EU countries.

Last week, British Airways announced an investment in US alcohol-to-jet fuel producer LanzaJet, with the two partners signalling their interest in deploying the LanzaJet technology and SAF production in the UK (see article).

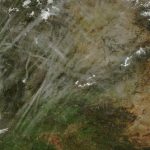

Photo: The Stanlow Manufacturing Complex (credit: Essar)

More News & Features

Regional SAF News February 2026

SkyNRG reaches financial close for Dutch 100,000-tonne SAF facility

Concrete Chemicals consortium secures €350m public funding for German eSAF project

UK regulator sets out guidance for providing emissions data to passengers booking flights

SAF One announces new investment and technology partners for Middle East SAF project

New initiative formed to accelerate SAF adoption and production in the Pacific Northwest